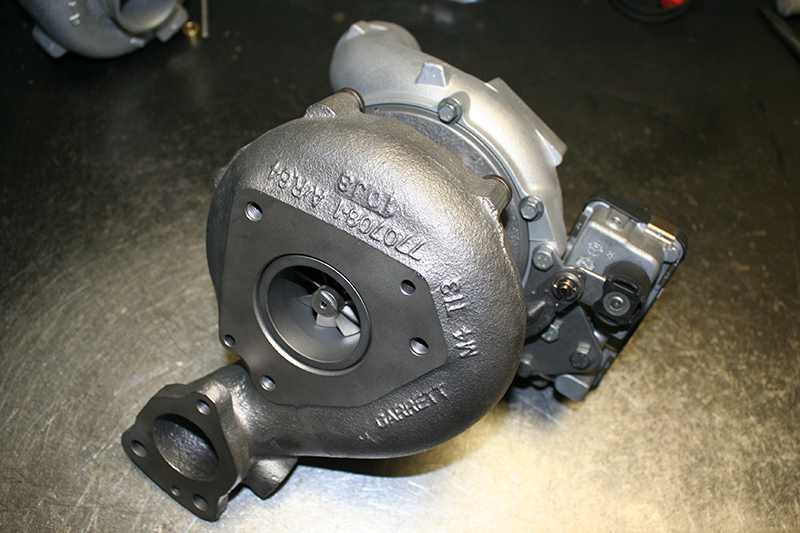

Our focus has always been singular quality. Every unit is assembled and balanced by Herman. Each turbo goes through an inspection procedure. Disassembly is carefully done as well. This ensures that the cause of failure is discovered. This information is passed on to the customer adding to the value of having us take care of your turbo.

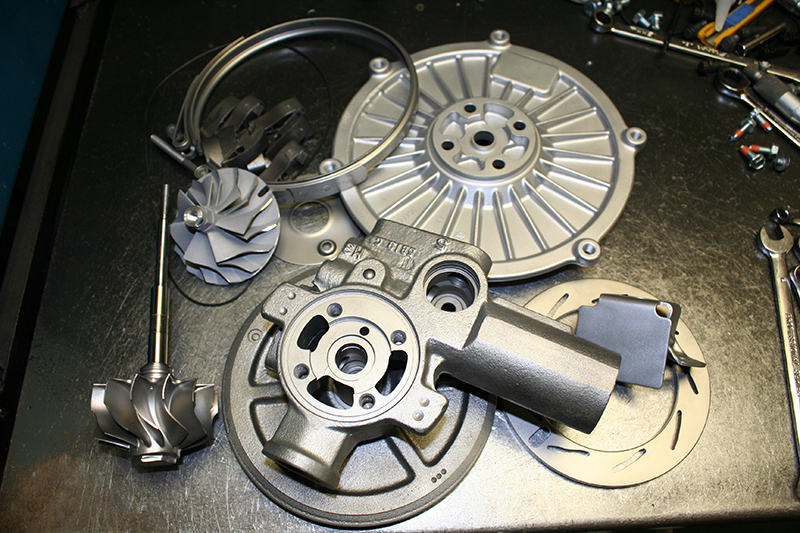

All the pieces are de-greased and inspected once more. The need for new components is decided at this point. Estimating the cost is next and with the customer's go-ahead we proceed further.

Our parts cleaning and refinishing process is more delicate in nature than most auto parts re-manufacturers. Carefully masking certain surfaces and using custom built media blasting equipment is necessary for a successful outcome.

We have a multi plane digital Italian balancer that ensures the individual and assembled rotating parts are often balanced to tighter specifications than factory new. We also offer just a balancing service. Please contact us if you wish to have a rotating assembly inspected or cleaned and balanced.

The turbos are assembled in a clean room. This controlled environment ensures that the final process is free from all sources of contaminants.

Many of our customers choose to have their turbo re-manufactured. We also offer exchange turbos for some popular applications. Receiving the old turbo back is vital to this service being an on-going program. We charge a modest refundable fee for the core. Once the core reaches our facility the core charge is reversed or refunded.